Munich, June 2022

- Innovations for the mobility of the future and a major milestone on the way to series production: first pre-series parts for mocci

- Digitally driven, fully connected and 100 % emission-free: mocci Smart Pedal Vehicles (SPV) set new standards in the field of steadily growing micro-mobility

- Numerous customer orders for mocci pilot projects

World Innovations „made in Germany “

Micro-mobility rethought: With the Smart Pedal Vehicles (SPV), mocci (mocci.com) enables mobility in urban areas at a completely new level. Digital, reliable, and sustainable. Thanks to innovative materials, mocci combines a novel production approach from large-scale manufacturing paired with a completely new software and system architecture.

Instead of steel or aluminum, the frames, rims, and other main components of the Smart Pedal Vehicles are made of recyclable high-performance polyamides. The significantly reduced number of components compared to the competition results in a safe, robust, durable, and low-maintenance system. All mocci components are developed and produced locally in a sustainable manner in Germany.

As a second core innovation, mocci for the first time relies on a digital chainless drive unit that adapts to individual driving behavior. The drive system of the series hybrid offers a completely new driving experience: individually adaptable to the driver, safe, low-maintenance, sustainable and fully networked. This enables the introduction of a new software architecture with countless digital business models.

An important milestone towards series production

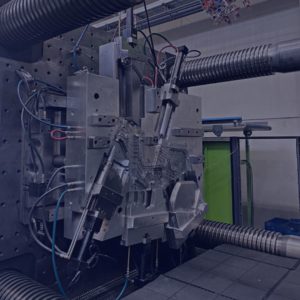

In cooperation with renowned research and development partners from Germany, CIP Mobility has revolutionized the concept of classic bicycles with mocci. mocci has developed a unique mold concept for injection molding that enables high volumes with consistent quality and high automation. In addition, a significant reduction of individual parts in the overall vehicle was achieved. Structural components such as frames and rims, for example, consist of just one part. Compared to conventional spoked wheels, the SPVs are therefore significantly safer and require less maintenance, achieve a new level of stability and durability, and offer numerous advantages, particularly in terms of total cost of ownership. All in all: no broken spokes, no broken chains, very low maintenance, and a high load capacity.

The local production “Made in Germany” is efficiently scalable and offers flexible and season-independent availability. “As a founder and entrepreneur, I am very proud that we have recently produced the first parts of the pre-series and thus have already mastered an important step on the way to series production!” says Dimitrios Bachadakis, Managing Director of CIP Mobility. Thus, mocci is on schedule for the production of the first pre-series vehicles. In addition, this step provides important insights into component quality, confirmation of product development and at the same time important experience is gained for the design of the further series process.

“The next step will be assembly runs, tests and certification of the SPVs, before we deliver to well-known B2B customers and pilot partners from various sectors in the near future,” continues Dimitrios Bachadakis.

Multi-Use & the start of the pilot phase

Thanks to diverse individual solutions for customers, a variety of inner-city and operational mobility scenarios can be realized with mocci. “We offer a real innovation for B2B customers,” says Dimitrios Bachadakis. With their low downtime and long service life, the Smart Pedal Vehicles offer enormous advantages, especially for commercial customers. The heavy-duty wheels can be used, for example, to deliver groceries, for courier trips, with an additional trailer as a compact service vehicle for urban areas, or for modern digital city sharing services.

The ongoing customer meetings and rollout plans underline the great interest. „The first customer orders and LOIs have already been received”, says mocci Managing Director Dimitrios Bachadakis. The start of a pilot phase with selected B2B customers of the SPVs is in fall 2022.

From Munich to the world

The major goal is to establish a sustainable and leading research and development position as well as local production in the field of micro eMobility in Germany – and successively build it up worldwide. With the innovation “Engineered & Made-in-Germany”, CIP Mobility wants to make the cities of this world more livable.

About mocci from CIP GROUP

mocci is a brand of CIP MOBILITY GMBH, which considers the topic of mobility holistically and in the context of the connected and digital city of the future. In its Smart Pedal Vehicles (SPV), mocci combines the aspects of digitalization, environment, urbanization, and human well -being. The SPVs are an innovative, individual, and sustainable solution for companies that want to operate flexibly, quickly and in an environmentally friendly way in urban areas. The idea for mocci was born in 2014 and the official product launch is planned for fall 2022. More at mocci.com.

About CIP GROUP

CIP MOBILITY GMBH with its brand mocci is part of the CIP Group (CIP Holding AG), which with its three business models Supply Chain Services, Digital Intelligent Mobility and Strategic Transaction Advisory has been focusing on sustainable trends & business models for years. The company was founded in 2004 by Yao Wen and Dimitrios Bachadakis as a management buy-out from Siemens AG and developed into a global group of companies. More at cipgroup.com.

Press contact

Head of Marketing

Nico Mischke

Oberanger 32 • 80331 Munich

Phone +49 89 724019-611

nico.mischke@cipgroup.com